The problem usually doesn’t show up in the first purchase.

The first delivery arrives on time.

The samples look good.

The pricing is competitive.

Everyone feels confident.

Then the second order happens.

A delay here.

A quality variance there.

A different finish, a missing detail, a changed spec.

Suddenly, procurement is back in firefighting mode—following up, escalating, explaining, and apologizing for issues that shouldn’t exist in the first place.

And the quiet frustration sets in:

Why is reliability so hard to maintain once a supplier “wins” the account?

Why Procurement Problems Are Rarely About Price

When supplier performance slips, price often gets blamed.

But experienced procurement teams know better.

Unreliability usually comes from deeper issues:

- High worker turnover

- Rushed production schedules

- Weak process discipline

- No real ownership of outcomes

Suppliers promise consistency—but their systems can’t support it.

The result?

- Specs drift

- Standards erode

- Procurement absorbs the risk

And even when pricing is good, the total cost of ownership quietly increases.

The Hidden Cost Procurement Pays for Unreliable Suppliers

Unreliable suppliers don’t just affect budgets.

They affect people.

Procurement teams spend time:

- Chasing updates

- Rechecking deliveries

- Managing complaints

- Justifying decisions internally

None of this appears on a purchase order.

But it shows up in:

- Lost productivity

- Internal friction

- Credibility risk

The irony is that procurement isn’t looking for perfection.

It’s looking for predictability.

What Procurement Teams Actually Want (But Rarely Say Out Loud)

Beyond pricing and specs, most procurement leaders want one thing:

Suppliers who don’t create work.

That means:

- Orders that arrive as expected

- Products that match prior batches

- Fewer explanations

- Less escalation

In short, suppliers that allow procurement to move on to the next priority.

Reliability is not a “nice to have.”

It’s operational relief.

The Shift: From Chasing Deals to Choosing Stability

At some point, smart procurement teams change how they evaluate suppliers.

They stop asking:

“How low can the price go?”

And start asking:

“How stable is this operation?”

That shift changes supplier selection dramatically.

Instead of flash and scale, they look for:

- Disciplined production environments

- Clear processes that don’t change weekly

- Teams that stay, learn, and improve

- Accountability embedded in daily work

This is where reliability starts—not in contracts, but in culture.

When Reliability Stopped Being a Guess

We experienced this shift firsthand.

After dealing with too many suppliers who performed well only at the beginning, we worked with a production partner whose approach felt different.

No rush.

No shortcuts.

No dramatic promises.

Just a clear process and steady execution.

The first order met expectations.

But procurement doesn’t celebrate first orders.

The second order did the same.

Then the third.

Same quality.

Same specs.

Same timeline.

No surprises.

That’s when we realized something important:

This supplier wasn’t managing orders. They were managing a system.

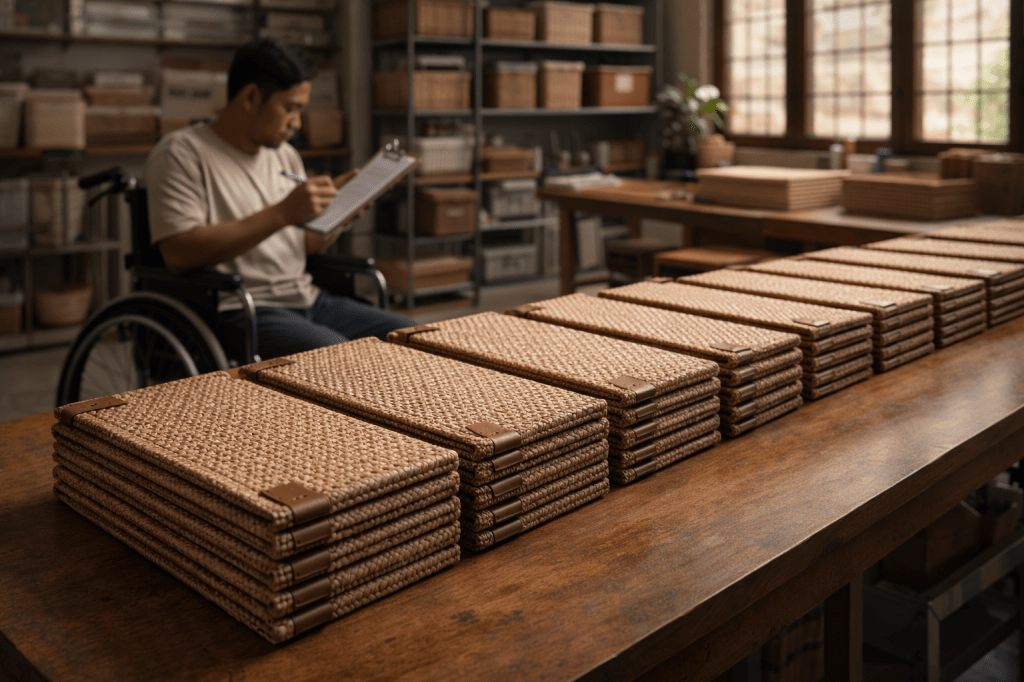

Why This Supplier Stayed Consistent

Over time, the reason became clear.

The production environment was stable.

- People weren’t rotating constantly

- Processes were followed, not improvised

- Quality checks were routine, not reactive

There was pride in repeatability.

Not speed for its own sake.

Not volume at the expense of standards.

Just consistent work, done properly.

The Detail We Learned Later (That Explained the Stability)

Only later did we learn something that procurement teams rarely hear upfront.

The products were made by Persons with Disabilities, employed through a structured livelihood program.

This wasn’t positioned as a selling point.

There were no emotional appeals.

It was simply how the workforce was built.

And suddenly, the stability made sense.

People with stable jobs protect the work that protects their livelihood.

They value consistency because it keeps work coming.

They take standards seriously because the outcome matters.

This wasn’t charity at work.

This was professional accountability.

Why This Matters for Procurement—but Doesn’t Need a Campaign

Here’s the key point for procurement leaders:

We didn’t stay with the supplier because of the social mission.

We stayed because the supplier performed.

The livelihood model didn’t replace standards.

It reinforced them.

That’s why this approach works at scale.

When reliability is tied to real livelihoods:

- Turnover drops

- Skills deepen

- Ownership increases

- Output stabilizes

Procurement benefits without carrying the burden.

The Outcome Procurement Actually Cares About

Because performance stayed consistent:

- Reorders became routine

- Planning became easier

- Internal trust improved

- Supplier risk decreased

Procurement stopped reacting and started operating.

And behind that stability:

- Workers had steady income

- Skills improved over time

- Livelihoods were sustained through demand, not donations

Impact wasn’t managed separately.

It was embedded in operations.

A Smarter Way to Think About Supplier Selection

For procurement leaders, the takeaway is simple:

Don’t just evaluate price and specs.

Evaluate stability.

Ask:

- Who actually does the work?

- How often does the team change?

- Is quality dependent on supervision—or habit?

- What happens when volume increases?

Suppliers who invest in people tend to protect processes.

And protected processes protect procurement.

Why Reliability Is the New Competitive Advantage

In an environment where disruptions are common, reliable suppliers are rare—and valuable.

They:

- Reduce risk

- Save time

- Protect credibility

- Lower long-term costs

And sometimes, they come from places procurement wasn’t trained to look.

Not because of sympathy.

But because of structure.

The Procurement Choice That Pays Off Long After the Contract Is Signed

If you’re responsible for sourcing, here’s the quiet truth:

The best suppliers don’t need constant oversight.

They don’t need explaining.

They don’t need defending.

They just deliver.

And when those suppliers also happen to create stable livelihoods for Persons with Disabilities, that impact doesn’t compete with procurement goals.

It strengthens them.

Because reliability isn’t built on promises.

It’s built on people who show up, follow process, and care about doing the job right—every time.

Leave a comment