The problem rarely looks serious at first.

The delivery arrives on time.

The product meets the general specification.

Nothing is technically “wrong.”

But something is… off.

The finish feels slightly different.

The alignment isn’t quite the same.

The color tone varies just enough to notice.

No one raises a red flag. Procurement accepts it. Operations adjusts. Someone explains it away as “within tolerance.”

And that’s how variance quietly becomes normal.

The Most Expensive Procurement Problem Nobody Tracks Properly

Procurement leaders spend a lot of time managing risk, cost, and compliance. But one of the most expensive problems rarely shows up cleanly on reports.

Variance.

Not defects.

Not failures.

But almost right.

Variance doesn’t stop operations outright.

It slows them down.

It creates:

- Rework that shouldn’t exist

- Extra checks that consume time

- Internal explanations that erode trust

- Brand inconsistencies that procurement ends up owning

The cost doesn’t show up on a purchase order.

It shows up in friction.

And over time, that friction compounds.

Why “Minor Differences” Are a Major Procurement Issue

From a supplier’s perspective, small differences are easy to justify.

“Same materials.”

“Same supplier.”

“Same process.”

From a procurement perspective, they’re not small at all.

Because procurement doesn’t operate in isolation.

Every variance forces:

- Operations to adjust

- Quality teams to re-inspect

- Managers to ask questions

- Procurement to explain decisions

And while each incident may seem manageable, the cumulative effect is significant.

Variance creates noise.

And noise consumes attention.

The Hard Truth: Variance Is Not a Quality Issue

This is where procurement conversations often go wrong.

Variance is rarely caused by bad workmanship.

It’s almost always caused by unstable systems.

Common root causes include:

- High worker turnover

- Informal or undocumented processes

- Production that changes based on who’s present

- Quality checks done after the fact, not during

In other words, quality exists—but repeatability doesn’t.

And without repeatability, procurement is always one delivery away from a problem.

Why Traditional Controls Don’t Solve the Problem

Procurement often responds to variance with more controls.

More inspections.

More documentation.

More supplier meetings.

These help—but only temporarily.

Controls manage output.

They don’t fix systems.

If the underlying production environment is unstable, controls simply add overhead without eliminating the root cause.

That’s why some suppliers pass audits but still produce inconsistent results.

They know how to comply—but not how to sustain.

What High-Performing Procurement Teams Do Differently

At some point, experienced procurement teams change how they think about the problem.

They stop asking:

“Are the specs correct?”

And start asking:

“Is this system built to repeat itself?”

That shift changes supplier evaluation entirely.

Instead of focusing only on price, capacity, and certifications, they look deeper:

- How stable is the workforce?

- How often do people rotate roles?

- Is quality enforced—or habitual?

- Does production depend on supervision or routine?

The best procurement teams don’t chase performance.

They design for predictability.

When Repeatability Becomes the Standard, Not the Exception

We experienced this shift after dealing with too many suppliers that delivered excellent samples—and inconsistent follow-through.

Eventually, we partnered with a production team whose output felt different from the start.

Not louder.

Not faster.

Just consistent.

The first order met expectations.

So did the second.

And the third.

No changes.

No adjustments.

No explanations.

That’s when it became clear:

This supplier wasn’t controlling variance after it happened.

They were preventing it from happening at all.

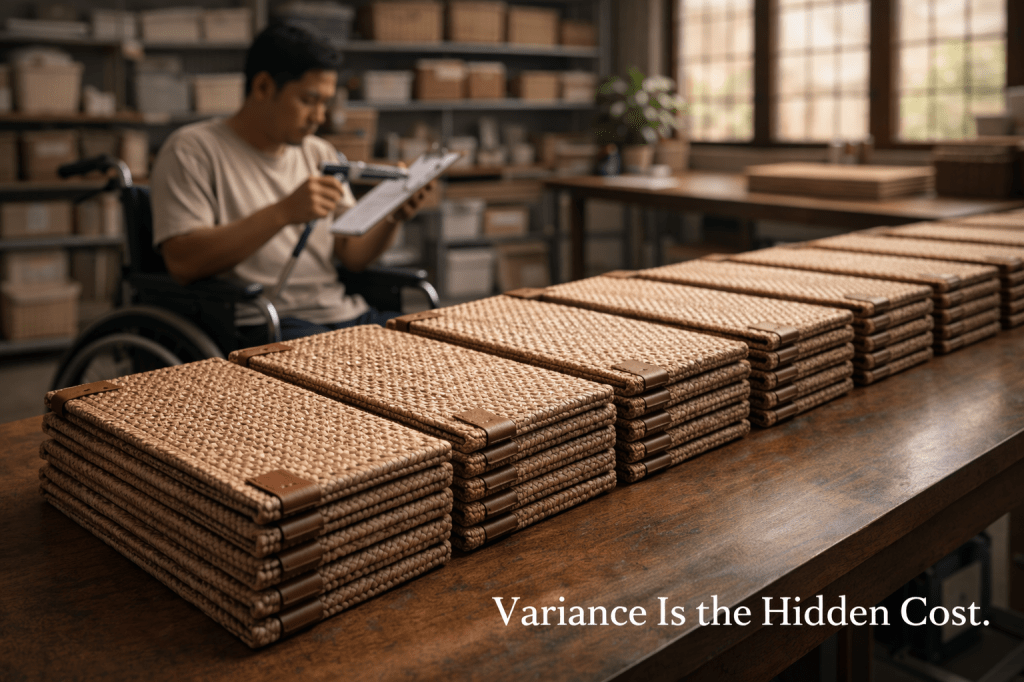

Why Variance Disappeared in This Environment

Over time, the reason became obvious.

The production environment was stable.

- The same people showed up consistently

- Tasks were clearly defined and repeated

- Quality checks were embedded in the process

- Work didn’t change depending on urgency

People weren’t improvising.

They were executing.

And execution, repeated over time, creates reliability.

The Detail That Explained Everything

Only later did we learn something that reframed the entire experience.

The workforce behind the production consisted largely of Persons with Disabilities, employed through a structured livelihood program.

This wasn’t positioned as a CSR feature.

There was no emphasis on advocacy.

It was simply how the operation was built.

And suddenly, the stability made complete sense.

Why Livelihood Stability Eliminates Variance

This is the connection procurement teams rarely get to see up close.

When people rely on work for long-term livelihood:

- Turnover drops

- Skill mastery increases

- Process adherence strengthens

- Ownership becomes personal

People protect systems that protect their income.

PWD artisans weren’t rotating in and out.

They weren’t rushing to move on.

They weren’t treating the work as temporary.

They were invested in getting it right—every time.

Not because of sympathy.

But because consistency sustained their livelihood.

Why This Matters for Procurement—but Isn’t a CSR Conversation

Here’s the critical point for procurement leaders:

We didn’t stay with the supplier because of the social mission.

We stayed because variance disappeared.

The livelihood model didn’t replace quality systems.

It reinforced them.

This is not charity driving performance.

It’s stability driving discipline.

And discipline is what procurement actually needs.

The Outcome Procurement Cares About Most

Once variance dropped, everything else improved naturally.

For procurement:

- Fewer escalations

- Less re-inspection

- Predictable planning

- Stronger internal credibility

For operations:

- Fewer adjustments

- Smoother workflows

- Less firefighting

For the workforce:

- Stable income

- Skill progression

- Long-term participation

Impact wasn’t layered on top of operations.

It was embedded inside them.

The Procurement Insight That Changes Supplier Strategy

The takeaway is not to source “for impact.”

The takeaway is to source for systems that sustain performance.

Procurement leaders should ask:

- Does this supplier’s workforce stay?

- Is quality built into routine or enforced externally?

- What happens to output consistency over time?

- Does the system protect against variance—or react to it?

Suppliers who invest in people tend to protect process.

Suppliers who protect process reduce procurement risk.

Why Eliminating Variance Is the Real Cost Advantage

Procurement doesn’t win by shaving cents off unit prices.

It wins by eliminating noise.

Variance creates noise.

Noise consumes attention.

Attention is expensive.

The best procurement decisions are the ones that:

- Don’t need defending

- Don’t require monitoring

- Don’t create follow-up work

They just hold.

The Procurement Decision That Pays Off Long After the Contract

If you’re responsible for sourcing, here’s the quiet truth:

The best suppliers don’t impress you once.

They perform the same way—every time.

And sometimes, the systems that make that possible come from places procurement wasn’t trained to look.

Not because of emotion.

But because of structure.

When work is stable, people are stable.

When people are stable, processes hold.

When processes hold, variance disappears.

And when variance disappears, procurement finally gets what it wants most:

Reliability without noise.

Leave a comment